High Voltage Coolant Heater | Automotive

400 V Variant Flyer Technical Data Sheet

800 V Variant Flyer Technical Data Sheet

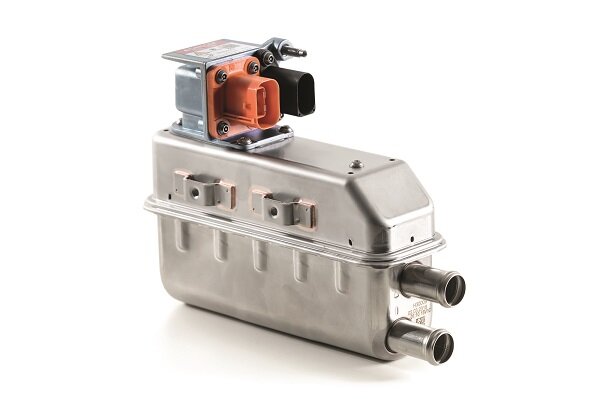

The world's smallest, lightest and most efficient Automotive High Voltage Fluid Heater for automotive thermal management, battery heating & interior heating.

• Heating power up to 6 kW respectively 7 kW

• Voltage range 195 - 450 V respectively 180 - 940 V

• Robust and field-tested wire heating technology

• Patented fluid guidance

• High energy efficiency of ~98%

HIGH VOLTAGE WATER HEATERs UP TO 7kW | 450V

High Voltage Water Heaters are electric water heating systems using tubular heating technology to heat the water circuit in electric, hybrid or fuel cell vehicles. As these vehicles hardly generate any engine waste heat, electric auxiliary heaters are required to provide sufficient heating for the vehicle interior.

High Voltage Water Heaters are compact heating systems with robust stainless steel housing for easy integration into the water circuit. The fluid can enter the lower housing chamber via two pipe connections and will be heated directly by tubular heating elements.The integrated power electronics, installed in the upper housing chamber, serve to control and monitor the heating elements and can be controlled by PWM signal or standard bus systems (LIN).

The built-in tubular heating elements have been especially designed for automotive applications and offer several advantages over PTC technology, e.g. high power at high water temperatures, a wider voltage range, and low inrush currents. The tubular heater’s resistance-to-temperature dependency allows for precise temperature control - for maximum reliability and safety.

High Voltage Water Heaters are available in different versions, depending on customer requirements, featuring an power output of up to 7KW and an operating voltage of up to 450V.